At Stable Fabrication, commitment to excellence is more than a principle—it’s the foundation upon which we build every project. Across all sectors, including motorsport, aerospace, and medical devices, we uphold a promise of quality that positions us as industry leaders. This dedication is backed by comprehensive quality control measures and a relentless focus on precision, safety, and reliability.

Advanced Technology for Precision and Reliability

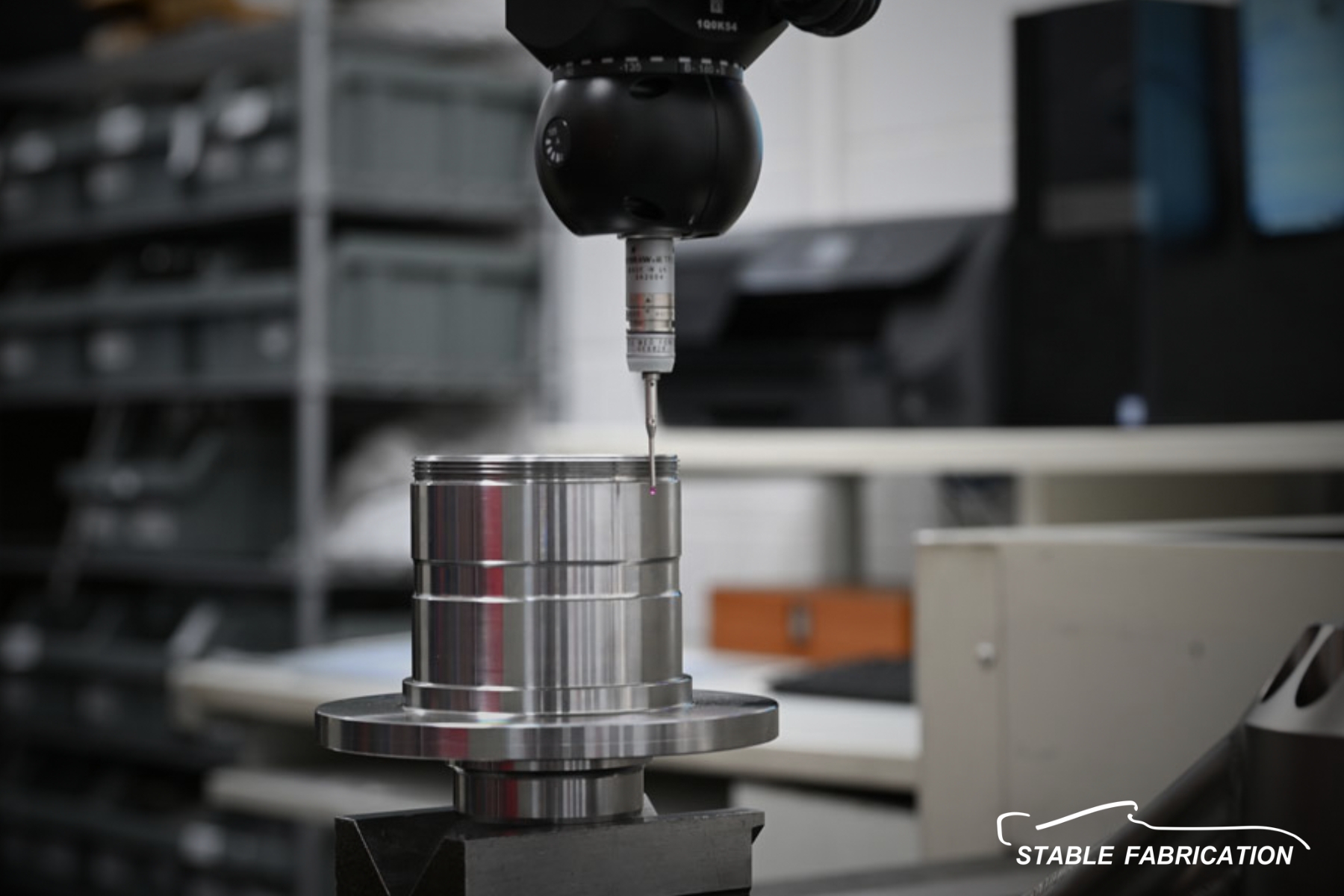

Central to our quality assurance strategy is our state-of-the-art Quality Control Department. Outfitted with the latest in inspection technology, our facility leverages advanced tools such as Coordinate Measuring Machines (CMM), Faro Arms, and Shadow Graphs, alongside a vast array of precise hand measuring instruments. These sophisticated resources allow our skilled technicians to perform detailed inspections, ensuring that each component meets exact specifications with unmatched accuracy.

Comprehensive Quality Assurance Services

To guarantee that our products surpass the highest industry benchmarks, we provide in-depth quality assurance services, including detailed inspection reports that outline the integrity and quality of each item. Beyond surface-level evaluations, our process includes material certification, Heat Treatment Certification, and Non-Destructive Testing (NDT) Certification. These verifications confirm that our production processes and materials adhere to stringent safety and performance standards.

Customisable Inspection Levels with PPAP

Understanding that no two projects are alike, we tailor our approach to meet specific client requirements. Through our Production Part Approval Process (PPAP), we offer varied inspection levels—ranging from initial sample inspections (Level 1) to comprehensive full production approvals (Level 5). This flexibility ensures that we maintain compliance and transparency throughout the manufacturing process, fostering trust and satisfaction with our clients.

Setting the Bar for Excellence

Our commitment doesn’t stop at meeting industry norms; it extends to setting new standards. With rigorous inspections and exhaustive documentation, Stable Fabrication delivers products that not only meet but exceed customer expectations. Each project, regardless of scale, benefits from our unwavering dedication to precision and excellence. Clients can trust us to deliver components that inspire confidence and reliability, project after project.

At Stable Fabrication, our promise is simple: to uphold the highest standards of quality and craftsmanship in every product we create. From the first inspection to the final approval, our focus on quality control ensures that we remain a trusted partner in the world’s most demanding industries.